Our Work

Yankee Composites believes service to our clients, friends, and fellow pilots, is of the utmost importance. The wing you fly holds the most valuable object around… you’re life!

Yankee Composites promises to uphold the highest standards when inspecting your glider.

We also guarantee that you will receive an honest assessment of the repairs or services that your equipment may require.

ASW-27 Sailplane Project

Jantar Glider Aileron Bearing Mount Failure

Jantar: Find aileron bearing problem

Bearing detached from mount

Jantar: Drill more holes

Holes drilled to get to bearings that detached from mount

Find all bearings – cut holes

Holes drilled in many places on each wing.

Patch, then paint

Holes are patched and then repainted.

PW-5 Glider Land Out Damage

Off field landings can be rough sometimes. The landing gear and belly needed repair and repainting.

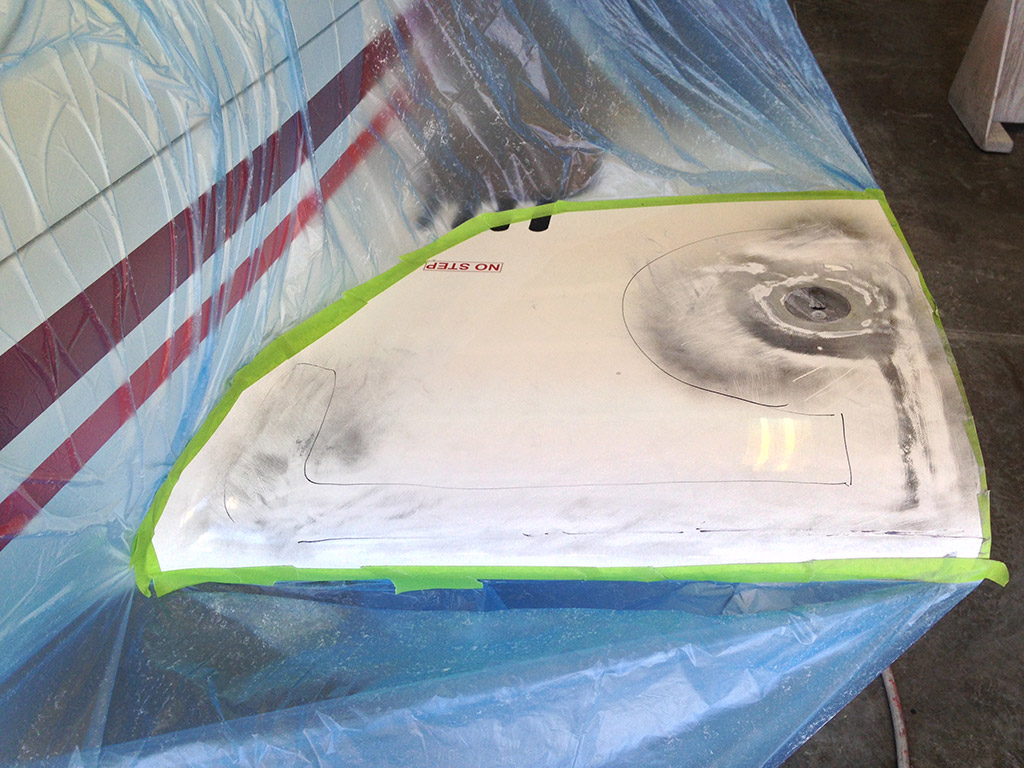

PW-5-landing gear & belly

Landing gear needed repair and belly needed patching

PW-5 gear and belly ready to paint

Repaired gear, composite patches, prime, ready to paint

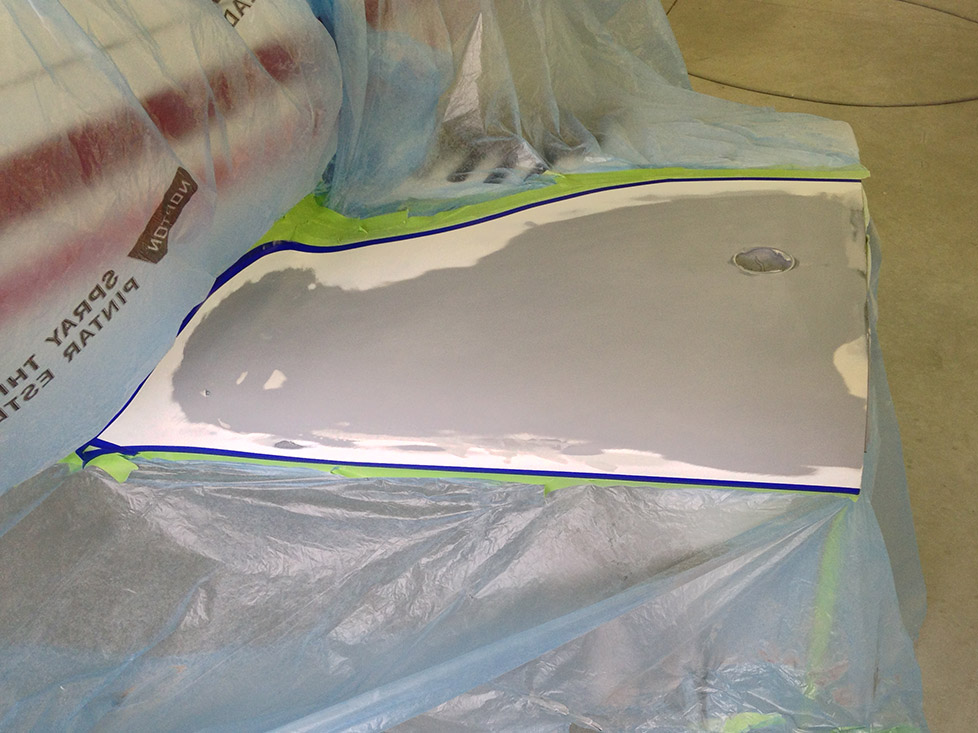

PW-5- gear & belly repaired

Landing gear and belly repaired and repainted.

Dynamic Light Sport Aircraft Fuel Tank Area

Dynamic Light Sport tank area

Ethanol dissolves epoxy finish

Damaged finish removed

Removed damaged surface, scraped and sanded

Surface filled and patched

Surface repaired, filled, patched, and sanded – it is ready to paint.

Ethanol damage repaired

Painted and ready to fly again. Watch out when using Ethanol fuels

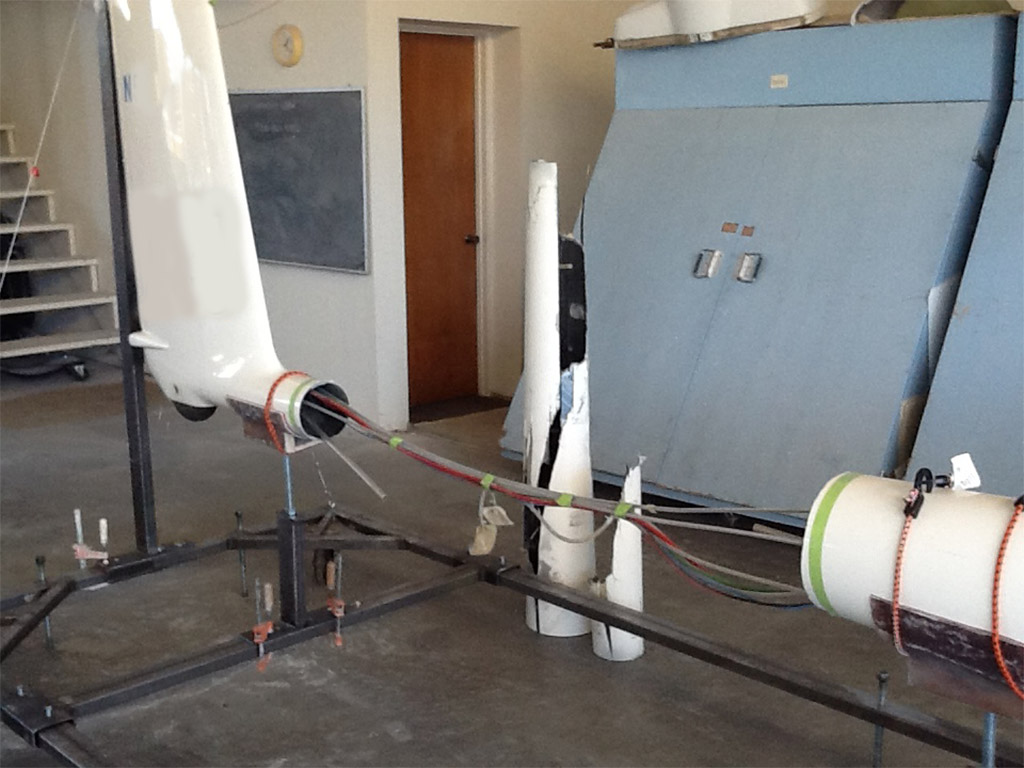

Schleicher ASW-27 Glider Tail Boom

ASW-27 land out incident breaks tail boom. The broken tail boom has been cut away is is standing next to the space left where it used to be. The glider is put on a special frame to align the fuselage in preparation for the new composite tail boom to be built.

ASW-27 Tail boom broken

ASW-27 broken tail boom part cut out, glider is on alignment frame.

ASW-27 Tail boom rebuilt

ASW-27 Tail boom rebuilt and vacuum pump is used to cure new surface

ASW-27 after test flight

ASW-27 has new tail boom, painted to match, going back in trailer

Grob-109 Motorglider Refinish

This Grob-109 was partially refinished and now looks almost as good as new.

Grob-109 refinish underway

Grob-109 Wings being refinished, large wings, lots of surface area

Grob-109 being polished

Grob-109 final finish on the wings.

Grob-109 refinished

Grob-109 ready for test flight, nice shine on the wings.

Grob-103 Glider Refinished Inside & Out

This Grob-103 looks great with new interior and new exterior finish.

Grob-103-Twin-II-Refurbished

Transformed Grob-103 with new interior and panel.

Grob-103 Looks new inside

Grob 103 Interior Refinished.

Grob-103 fully restored

Grob 103 Fully Restored inside and out.